Imagine torquing a fastener to 250 ft/lbs without any opposite force felt to the tool or your body. That’s the magic in the HYTORC LION Gun portable bolting system. To be honest, it’s not magic, but it is the years of development and engineering that HYTORC brings to a handheld portable tool.

Looking at the HYTORC LION Gun portable bolting system, you may mistake it for a typical cordless impact wrench. This couldn’t be further from reality. The LION Gun is a sophisticated battery operated torque multiplier that can deliver up to 250 ft/lbs of fastening torque without a sweat, to the tool or the operator. Add to this precision torque measuring, and the ability to export all the detailed data from the tools recent jobs. Do THAT with an impact wrench!

[adsenseyu1]

Who is HYTORC?

HYTORC headquarters are in New Jersey and they bring over 45 years of experience in industrial bolting systems. Steel mills, mining equipment, refineries, power plants, distilleries and even wind turbines rely on HYTORC’s bolting application solutions. They don’t stop there, HYTORC has an engineering team available to design a custom solution for your specific application.

HYTORC headquarters are in New Jersey and they bring over 45 years of experience in industrial bolting systems. Steel mills, mining equipment, refineries, power plants, distilleries and even wind turbines rely on HYTORC’s bolting application solutions. They don’t stop there, HYTORC has an engineering team available to design a custom solution for your specific application.

HYTORC not only designs and manufactures bolting systems, but they also maintain, service and even train onsite at your location. In addition to multiple facilities in the US, HYTORC also has locations in Japan, Germany, England and many other countries. It seems there are no geographical boundaries they can’t overcome.

HYTORC LION Gun Portable Bolting System Features

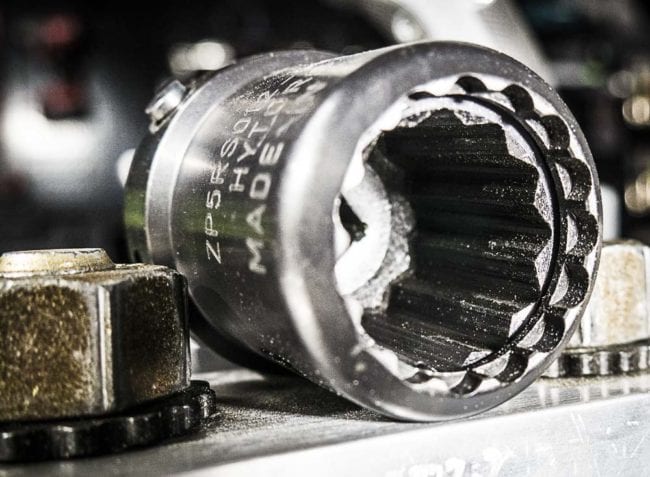

The business end of the HYTORC LION Gun has the 1/2” square anvil to receive normal sockets, however a splined reactionary-arm gear resides just behind the square. The 1/2” anvil uses pin and o-ring type sockets, and the reactionary arm has a push-button detent to lock the arm onto the spline drive. When the LION Gun engages, the socket turns (action) and the reactionary arm provides the opposite reaction against the bolt/fastener beside, providing safe tightening.

The business end of the HYTORC LION Gun has the 1/2” square anvil to receive normal sockets, however a splined reactionary-arm gear resides just behind the square. The 1/2” anvil uses pin and o-ring type sockets, and the reactionary arm has a push-button detent to lock the arm onto the spline drive. When the LION Gun engages, the socket turns (action) and the reactionary arm provides the opposite reaction against the bolt/fastener beside, providing safe tightening.

A typical trigger provides single-speed power to the socket. A small electronic switch on the rear of the gun, underneath the main body, allows for direction changes (forward/reverse). Also, a small illuminated digital screen resides on the rear of the main body with 3 red soft-rubber action buttons beneath the screen. Quickly pressing the center button will turn on the HYTORC LION Gun portable bolting system.

Two 18-volt Lithium-Ion 4Ah batteries are included in the kit. Each battery has a charge indicator on the side with 4 green LED lights. Rubber overmolding protects the sides and bottom of the battery from accidental drops and bumps. Further rubber overmolding is found throughout the handle and body of the LION Gun as well.

HYTORC Lion Gun Internals

Power is provided by a BLDC (Brushless DC) motor connected to a non-impacting industrial-strength gearbox. This allows the LION Gun bolting system to deliver torque faster, more accurately and more reliably than manual click-type wrenches and impacts. Furthermore, this HYTORC LION delivers excellent power to weight due to the use of aerospace-grade alloys.

Power is provided by a BLDC (Brushless DC) motor connected to a non-impacting industrial-strength gearbox. This allows the LION Gun bolting system to deliver torque faster, more accurately and more reliably than manual click-type wrenches and impacts. Furthermore, this HYTORC LION delivers excellent power to weight due to the use of aerospace-grade alloys.

From the digital display and red buttons, the user can set the desired torque of fasteners to be tightened. Next, attach the socket to the fastener and hold the trigger, hence the HYTORC LION Gun portable bolting system does the rest. This is done with very little noise and even less vibration. This system delivers repeatable torque to fasteners, being very precise, withing 5% variation. The Hytorc bolting system provides simpler and safer results.

Other Angles

In addition to precision tightening and torquing bolts, the LION Gun bolting system takes this a step or two further. Many newer fasteners require a torque value to “seat” the bolt or fastener, then an additional xx-degrees of angle is input to fully set the clamping pressure of the bolt. If you have had the pleasure of replacing cylinder heads on newer cars, then you should understand this concept. After decades of only torquing bolts to a certain foot-pound (in-lb, Nm, etc.), engineers have determined this new ‘angle’ approach provides much more accuracy with less variables to interfere.

In addition to precision tightening and torquing bolts, the LION Gun bolting system takes this a step or two further. Many newer fasteners require a torque value to “seat” the bolt or fastener, then an additional xx-degrees of angle is input to fully set the clamping pressure of the bolt. If you have had the pleasure of replacing cylinder heads on newer cars, then you should understand this concept. After decades of only torquing bolts to a certain foot-pound (in-lb, Nm, etc.), engineers have determined this new ‘angle’ approach provides much more accuracy with less variables to interfere.

With 250 ft-lbs on tap with this HYTORC LION Gun portable bolting system, things can get tight and in a pinch, in a hurry. To help alleviate this, HYTORC has added yet another feature to the LION Gun. In addition to the torque and angle value for tightening, the user can even add x-degrees of angle to back off the socket, once the torque and angle tightening is complete.

Example and Operation

Example: The user inputs 60 ft-lbs on the digital display, then adds 120° of angle. Finally, the operator can then add 3° of reverse angle. The reason here is that putting 60 ft-lbs of force on the fastener, then adding 120° rotation, there is a lot of force and pressure on the bolt and socket (even on the reactionary arm). It may be tough or near-impossible to remove the socket from the fastener. The 3° of reverse angle backs off the socket, but not enough to loosen the fastener.

Operating the LION Gun is very easy once all the parameters are input. Let’s assume the example above. The operator would place the socket on the fastener, with the reactionary arm resting against the next fastener. Assuming the LION Gun is still attached to the socket. The user would then pull the trigger and Hold. Don’t let go until all operations are complete. The Gun will tighten the bolt to 60 ft-lbs, stop for a brief second, then add 120° of rotation to the bolt, stop for a brief second, then reverse 3° and stop. This is all completed by just holding down the button.

Job Tracking and Spreadsheets

Not only does the HYTORC LION Gun aim to make the sweat-work more efficient, the technology within can also help with the pencil-pushing and job-tracking as well. With the digital screen, the user can provide a job number. The subsequent bolt tightening will be labeled with said job. Ex. each job can be a flange. Each flange gets a new job number. At the end of the day, with a simple USB cable and tablet, the operator can export all the job/s data to a CSV spreadsheet for reporting.

HYTORC LION Gun Options

One reactionary-arm is supplied with the HYTORC LION Gun kit, but there are many other reactionary-arms available for the LION. In addition to the reactionary-arms, HYTORC has engineered a system that even further eliminates the pinch-points and torquing in tightening fasteners. A special HYTORC socket is like 2 sockets in one. The primary fastener socket attaches to the square anvil this is surrounded by a second socket that attaches to the reactionary spline.

One reactionary-arm is supplied with the HYTORC LION Gun kit, but there are many other reactionary-arms available for the LION. In addition to the reactionary-arms, HYTORC has engineered a system that even further eliminates the pinch-points and torquing in tightening fasteners. A special HYTORC socket is like 2 sockets in one. The primary fastener socket attaches to the square anvil this is surrounded by a second socket that attaches to the reactionary spline.

This special socket works in tandem with the HYTORC washer. The HYTORC washer includes hash-mark engravings on the flat surface, on one side of the washer. The outside edges of the washer appear to have rounded teeth. The aforementioned outer socket meshes with the washer, while the inner socket meshes with the fastener/bolt head. Now, the action and reaction (opposing forces) are being controlled inside the walls of that HYTORC socket. The answer is a non-pinching, virtually no twist, bolting system, up to 250 ft-lbs, in the palm of your hand.

Final Thoughts

We have the HYTORC in the shop, but we have yet to place it onsite for testing applications. There is no doubt, this is a solid machine. There is no vibration when torqueing/tightening, and there is virtually no twist, using the HYTORC socket/washer, when torquing fasteners. The ability to torque and add angle with a single unit definitely adds usability and convenience. Power seems to be more than adequate, even when testing to 250 ft-lbs in a bench test.

[adsenseyu2]

Rubber overmolding allows for easy gripping. Even thought aerospace alloys have may have lightened it up, this is still a heavy tool. At the same time, you’re not carrying this around running out 1/4” bolts. This is made for industrial use and performing “real” work. The electronic forward-reverse switch causes a little issue, since it’s tucked under rear-main body, right where the user’s hand slides. On more than one occasion, our hand bumped this switch, changing from reverse to forward. We’re hoping to see a change in this switch for future versions.

Rubber overmolding allows for easy gripping. Even thought aerospace alloys have may have lightened it up, this is still a heavy tool. At the same time, you’re not carrying this around running out 1/4” bolts. This is made for industrial use and performing “real” work. The electronic forward-reverse switch causes a little issue, since it’s tucked under rear-main body, right where the user’s hand slides. On more than one occasion, our hand bumped this switch, changing from reverse to forward. We’re hoping to see a change in this switch for future versions.

HYTORC states they area consistently improving upon existing products, so we’ll be excited to see what comes of the LION Gun in the future. This seems to be a great tool, but it definitely needs the correct application to prove the value. Finally, HYTORC says their latest bolting systems area guaranteed stop leaks on pressurized vessels and eliminate unwanted nut loosening. Also, all HYTORC products are covered by our worldwide one-year no-questions-asked warranty. This warranty includes free parts and labor

To find out more about the HYTORC LION Gun portable bolting system and more, click here.

Leave a Reply