In this third installment of our “Training the Apprentice Series” on grinders and their various accessory options, we’re going to take a look at another set of common options, bonded cut-off wheels and diamond cut-off wheels. If this is your first time with this series, or you’re new to grinders in general, maybe take a minute to read up on the introductory article about grinders and their applications and accessories. The second part covers hard grinding wheels vs flap discs.

[adsenseyu1]

If you’ve come this far with the series, you’ve probably realized the versatility of the die and angle grinder. Grinding, cutting, sanding, notching, polishing, sharpening, and cleaning are all possible, depending on the wheel you’ve chosen. In this article, we’ll be looking at two options that revolve around the task of cutting through hard material. Bonded cut-off wheels and diamond cut-off wheels both excel at cutting work, but each has its pros and cons. Let’s take a look at each. Hopefully, by the end of it, you’ll be able to make an informed selection more suited to your particular need.

Bonded Cut-Off Wheels

These wheels seem to be the standard for cut-off wheels that you’ve probably seen the most frequently. The basic design of the bonded cut-off wheel is almost identical to the bonded grinder wheel we talked about in the last article. A resinoid bonding material holds thousands of sharp, abrasive grains together so that the wheel can cut effectively. As the bonding and the grains wear away, new, sharp grains are exposed, maintaining the wheel’s cutting efficiency.

These wheels seem to be the standard for cut-off wheels that you’ve probably seen the most frequently. The basic design of the bonded cut-off wheel is almost identical to the bonded grinder wheel we talked about in the last article. A resinoid bonding material holds thousands of sharp, abrasive grains together so that the wheel can cut effectively. As the bonding and the grains wear away, new, sharp grains are exposed, maintaining the wheel’s cutting efficiency.

Bonded abrasive cut-off wheels come in two main varieties: a flat, type 1 wheel and a type 27, which sports a raised center hub. Some of the decision about which one to use will come down to your own preference, although depending on the tool manufacturer’s suggestion, you might not have a choice. You might find yourself limited by the size of the guard on the tool as well, but when in doubt, read the manufacturer’s specs.

As with grinder wheels, the grains in these cut-off wheels can come from a variety of materials. Aluminum oxide works well with steel, while silicon carbide works well for nonferrous materials. Zirconia alumina and ceramic alumina are also both viable options for a variety of different applications. These tend to last longer than the aluminum oxide wheels, but they cost a bit more too.

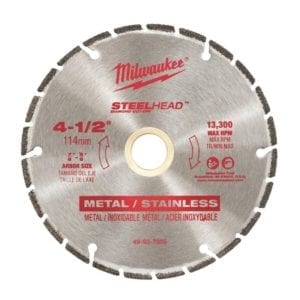

Diamond Cut-Off Wheels

An alternative to the abrasive cutting wheel, the diamond wheel consists of a metal wheel covered on its cutting edges with a diamond coating. Basically, polycrystaline diamond is manufactured in a high-intensity laboratory process. Diamond particles get fused with a carbide substrate and brazed onto a tool body to provide the wheel’s cutting edge. Since diamonds have such a high resistance to wear and tear, diamond cut-off wheels will outlast their bonded abrasive counterparts by a significant margin. In addition, diamond cut-off wheels can stand up to a variety of materials, like steel, sheet metal, stainless, rebar, ceramic, stone, etc.

Pro’s And Con’s

Both the bonded cut-off wheels and diamond cut-off wheels have a few pro’s and con’s to consider. Over the life of the wheel, the bonded abrasive wheel will cut faster in most applications than the diamond wheel. But, it will wear out much faster as well. I’ve been told that diamond wheels cut faster for the first few cuts, then drop off significantly. However, after the initial drop-off in speed, the cutting efficiency stays pretty consistent until the blade wears out. Meanwhile, the high cutting speed of the bonded wheel stays consistently fast, but you might have to change out worn discs pretty regularly.

Diamond cut-off wheels will tend to be the safer of the two options. Bonded cut-off wheels tend to throw off more sparks than diamond cut-off wheels, since both the work material and the grains and bonding of the wheel are being simultaneously ground down. This is not the case with diamond wheels, as the only thing generating sparks will be the work material. Granted, more sparks looks way cooler. But, if you happen to be working near anything flammable, bonded abrasive cut-off wheels might give you more trouble.

Also, breakage occurs more frequently with bonded wheels as well. Should you bind up your wheel in the work material, the chances of a bonded wheel exploding become much greater than the sturdier metal base of the diamond cut-off wheel. Of course, the chances of this happening are mitigated by following manufacturer recommendations for speed and material, but the fact remains that bonded wheels are just more brittle.

While you have a greater selection of options with a bonded disc, a diamond wheel probably has a greater spread of what materials it can handle. It is probably also going to be more effective with ceramic tiles and concrete.

Cost Vs Benefit

Another consideration comes down to cost. Bonded abrasive cut-off wheels cost less than their diamond coated counterparts. Of course, you will wind up replacing them more often, which offsets their overall cost when compared to a high initial cost of the diamond wheel. A $2 bonded wheel seems much cheaper than a $13 diamond cut-off wheel until you consider that you might have to use 10 of them to get through the same amount of cutting. At that point, the cost-per-cut of the diamond wheel is much cheaper than the bonded wheel. Ultimately, your decision will revolve around how much work you’ve got ahead of you, and how much you’re willing to spend.

[adsenseyu2]

Final Thoughts

Ultimately, you have a few considerations to make when deciding which wheel suits your needs best. What material are you trying to cut? How important is cutting speed to you, or is safety your number one concern? Is versatility important? Finally, how much are you willing to spend?

Both bonded cut-off wheels and diamond cut-off wheels have their merits. There probably isn’t a clear-cut “better” choice for most applications. Although you will find a few jobs for which a diamond wheel might operate more efficiently, like tile and stonework, your choice with most applications will come down to a matter of preference.

Of course, whichever way you lean, you will want to do things to extend the life of your wheel while also keeping yourself safe. Use a grinder that offers a good amount of amperage; more amps equals more torque. Be sure not to use too much pressure when cutting, and let the grinder do the work for you. It is good to know that the thinner your wheel, the more susceptible it is to bending and breaking in a jam. Before using your grinder, check your cut-off wheels for signs of damage, wear, or grime. And finally, practice proper safety techniques; the differences between cut-off wheels won’t matter all that much to you if you’ve put yourself in the hospital.

Leave a Reply