Having a welder in the shop is always a plus. The problem is, sometimes there’s just nowhere to put your stuff to be welded. Welding tables with steel plate tops are expensive to buy and even expensive to build yourself. If you tend to weld smaller pieces and parts, there is a cheaper solution. The Klutch welding table is only $89, so it fits the budget for most.

Having a welder in the shop is always a plus. The problem is, sometimes there’s just nowhere to put your stuff to be welded. Welding tables with steel plate tops are expensive to buy and even expensive to build yourself. If you tend to weld smaller pieces and parts, there is a cheaper solution. The Klutch welding table is only $89, so it fits the budget for most.

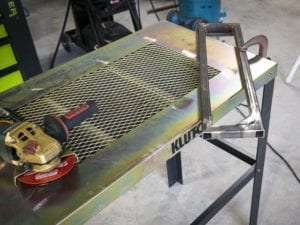

The Klutch table measures 20-inches wide by 38-inches long. With a 30-inch height, the table is easy to get around for welding, grinding, and cutting. Grounding lugs allow you to attach the work lead to the table, instead of your work-piece. Furthermore, work lead hook and a torch holder add convenience for when not in use.

[adsenseyu1]

Klutch Welding Table Assembly

The welding table arrives in a box with about 12 pieces, plus a bag of screws, nuts, bolts, and washers. Assembly of the table is mostly fastened with 10mm bolts and nuts. I grab our Makita Sub-compact CX200RB 18V Combo Kit with a 10mm socket, as well as a 10mm wrench.

The welding table arrives in a box with about 12 pieces, plus a bag of screws, nuts, bolts, and washers. Assembly of the table is mostly fastened with 10mm bolts and nuts. I grab our Makita Sub-compact CX200RB 18V Combo Kit with a 10mm socket, as well as a 10mm wrench.

Within 10 minutes, most of the table is complete. Now, just to flip it over to install the last few pieces. The catch tray and welding lead hangers attach with Phillips screws. Finally, the ground lugs are larger nuts and bolts that attach to both sides of the table’s short ends.

Welding and Grinding on the Klutch Welding Table

This is perfect timing, as I need to re-fab a corner on a square-tube frame. For clearance, one of the 90° corners needs to be 45°. After cutting a short piece of tubing with a 45° on each end, it was time for welding. I grab the ground lead and attach to the ground lug on the table. A quick tack weld on each corner of the tubing, and then I finish the welds. Now it’s time to cut off the 90° corner.

To cut the corner off my square-tube frame, I need to clamp it down. Using a C-clamp on this Klutch table is somewhat cumbersome. The lip surrounding the bottom of the table is less than an inch wide. Not much area for clamping. It does work out and I cut the corner out.

To cut the corner off my square-tube frame, I need to clamp it down. Using a C-clamp on this Klutch table is somewhat cumbersome. The lip surrounding the bottom of the table is less than an inch wide. Not much area for clamping. It does work out and I cut the corner out.

Grounding works well from the grounding lugs, and I have no problem with the arc. The topside of the Klutch table has a mesh top to let any slag or grinding residual fall through. With the tray on the bottom, all this residual is trapped until tray removal for discarding the pieces.

Final Thoughts

If you’re a DIYer or in another trade that needs a welder from time to time, the Klutch welding table may be a great option for you. It’s cheap, easy to setup, light, and doesn’t have a big footprint. On the flip-side, if you’re a fabricator, it’s probably not a good choice. This is not something that will be used for clamps and jigs, assuring flat and level surfaces. I must say that it works well for small jobs and it’s easy to move around.

If you’re a DIYer or in another trade that needs a welder from time to time, the Klutch welding table may be a great option for you. It’s cheap, easy to setup, light, and doesn’t have a big footprint. On the flip-side, if you’re a fabricator, it’s probably not a good choice. This is not something that will be used for clamps and jigs, assuring flat and level surfaces. I must say that it works well for small jobs and it’s easy to move around.

The Klutch welding table is available in this 20” x 38”, item# 48373. Other sizes and options are available as well through Northern Tool. To get your Klutch table, click here.

Leave a Reply