Among all of our sites, we’ve talked a lot about the features you’ll want to consider before buying a drill, an impact driver, and most recently, a reciprocating saw. Today, we get to flesh out all those things you’ll want to know about a table saw; we’ll talk about all of the bells, whistles, and doohickeys to look for. None of those are carpentry terms, by the way. But, the table saw is perhaps the highest-ranking tool in all of woodworking, the main implement for the hobbyist and contractor alike. It allows long rip cuts, crosscuts, bevels, and miters – making quick work of big jobs with a work surface, guide, and blade combined. We know that a lot of you might need to get into this sort of woodwork, and that there stands a real chance of finding yourself in front of a pile of available table saws for sale. When that happens, we think it could be helpful to know some of the things that the Pros look for in a table saw.

[adsenseyu1]

Table Saws For Sale Here! Get Your Red, Hot Table Saws!

Let’s face it: there are a lot of table saws for sale on the market these days, and the options can be overwhelming. Between various sizes, styles, power ratings and drive options, voltages, cut capacities, and safety features, there can be a lot of information to sift through and consider. We tried to break it all down for you, and in the following sections, we’re going to look at all the various things to consider to fit your particular needs.

Table Saw Styles

The first thing you’ll want to decide is the type of table saw you need. Check out our guide to choosing the best table saw for the job for a more in-depth look at table saw styles. But, in the spirit of saving everyone some time, here’s the gist of what you should know: there are a few types of table saws available.

Your “benchtop”, portable style will probably cost the least, but it will also probably provide less power than bigger saws. They are placed on top of a bench or table, or they can sometimes come with legs that you’ll assemble and purchase separately. Before you dive into purchasing this type of saw, you’ll definitely want to check out the quality of the fence, blade lifting mechanism, and beveling mechanism. Blade wobbles and a shoddy fence can knock your cuts off- square, leading to frustration and a mediocre final product. So, be aware that, generally, you get what you pay for.

The “jobsite” style of table saw is similar to the benchtop style, though they generally have a more robust motor and a wheeled folding stand for easier portability. The fences generally function better, and the saw will have better cut capacities. Again, check for the quality of the mechanisms before you buy.

“Contractor” style table saws typically come with an integrated, rolling stand, and offer more power. The motor will hinge off of the rear of the saw, driving the blade. This style kind of represents the “sweet spot” for most people who require portability and higher quality work.

Cabinet Table Saw

Where the previous styles are somewhat interchangeable, cabinet style saws offer power at the expense of portability. Cabinet table saws, like this one from Rikon, are heavy and stay put in the shop. They feature a closed base, and they’ll need a 220V outlet. They will also cost more than the lighter-duty, more portable styles. But, because of their weight, they will offer more stability, durability, and power.

Motor Power

As you might imagine, table saw power increases from Benchtop through Cabinet iterations. It would be nice if you could quickly compare power among saws, but that would be too easy! Besides, maybe a little math to get you warmed up is exactly what’s need as you measure lengths and angles for your project. You’ll notice that table saw motor power typically shows up in Amperes. They range from roughly 13 to 18 amps, with most being 15. Others use horsepower with a range of 1 to 2 HP for Benchtops through Contractor and 3 to 5 HP for cabinet saws, although more powerful saws are available.

Volts Matter

One complicating factor to your setup is the motor’s Voltage. Most table saws will use standard 120V because they’ll plug into a wall outlet or equivalent. But Cabinet table saws and other industrial/commercial saws with more powerful motors require 240V which, of course, requires special electrical accommodation.

Drive Type

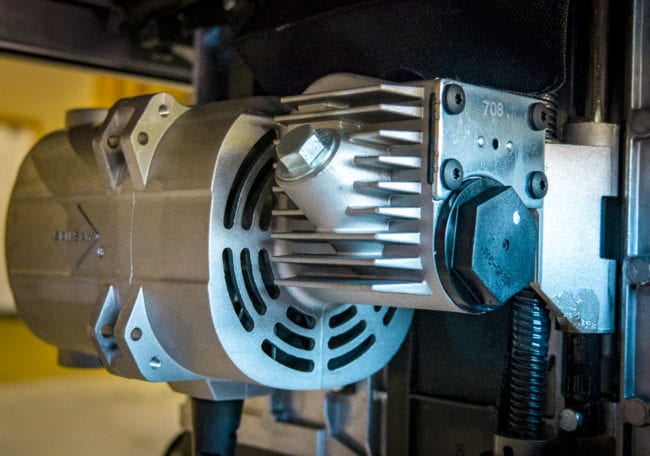

Table saw motors come in one of two designs: direct drive with universal motors and belt drive with induction motors. Direct drive motors get their name from the direct connection from the motor shaft to the blade. They are small, light, and low maintenance. As such, you’ll find these motors on Benchtop and Jobsite table saws. Skilsaw uses their worm drive motors in their portable and heavy-duty Jobsite models.

Belt drive motors may be bigger, slightly higher maintenance, and more expensive than their direct drive brethren, but they are more powerful and well-suited to hardwood and big jobs. Contractor and Cabinet table saws will likely sport belt drive motors.

RPM

For Benchtop and Jobsite saws with direct drive motors, the motor RPM is the blade RPM. If you’re considering a Contractor or Cabinet saw, it’s a different story. That’s because the blade is driven by a pulley whose diameter is different than the blade, and therefore has a different RPM. Be sure you know which RPM value the manufacturer measured. In any event, table saw RPM ranges from around 3,450 to 5,000.

But guess what? Most tradesmen will tell you they don’t pay much attention to the RPM. It’s the blade selection that’s more important to them. Still, a higher RPM is appropriate for Benchtop and Jobsite saws that rip softer woods. With harder woods, less is more as a higher RPM can cause the blade to burn the wood. RPMs toward the low end of the range are more likely on Contractor and Cabinet table saws.

Arbor & Trunnion

The arbor and trunnion are the components that hold the blade and allow it to move up, down, and at angles. Their quality and substantiveness increases with saw power and price. The arbor – the shaft that goes through the saw’s hole – is commonly 5/8-inch in diameter. However, Cabinet and commercial saws can have arbors up to 1-inch. You’ll just want to know what size your saw has before buying blades.

The front and rear trunnions are connected by the yoke and serve to stabilize and align the blade as it does its work. Although trunnions are often overlooked, they contribute greatly to the quality of the cut. Fine woodworkers and others that need precision cuts should pay particular attention both the quality and construction of the trunnions. If they are bolted to the table saw base, it will be easier to bring the blade into alignment with the miter gauge and fence than if they are attached to the underside of the table.

Table & Fence

Lower priced table saws (Benchtop and Jobsite) sport aluminum tables while higher end (and less portable) saws will have cast iron tables. It’s easy to understand why manufacturers must make tables to a very small flatness tolerance.

Although you won’t need the fence for every cut, it’s a critical component of table sawing. It gives you a surface to push against to guide a straight cut through the material. As such, the fence system needs to be square to the blade to make straight cuts. Cheaper saws will have fences that can easily move out of square as they slide along the surface of the table. Avoid these like the plague. The fence system should be foolproof and easy to keep square to the blade. A fairly new innovation from DeWalt is the rack-and-pinion fence system that makes adjustment easy. Hitachi’s C10RJ followed with the same design. Higher end saws will have higher end solutions.

Rip & Outfeed Capacity

The fence constrains a table saw’s rip capacity – or the maximum distance from the fence to the blade. This is the widest rip (or cross) cut the saw can make. Benchtop and Jobsite saws range from about 24-inches at the skinny end to the Hitachi C10RJ’s 35-inches. If you’ll need wider cuts than simply ripping 4×8-foot sheets of plywood in half lengthwise, be sure to look for the appropriate rip capacity.

Outfeed capacity is almost always the depth of the table. Cabinet saws likely have a big enough table to support outfeed. But tradesmen using a Benchtop, Jobsite, or Contractor table saw can opt to put a sawhorse or other support to hold the material after it passes the blade (or just have someone hold/guide it!). But it’s important to mention that the Hitachi C10RJ has a couple inches of extendable outfeed capacity, too.

Blade, Throat Plate, and Dado Capacity

Standard table saw blade diameter is 10 inches. By now, of course, you’ll know there are exceptions to the rule, especially on the higher-end Cabinet saws. But for most material, this 10-inch blade will give you somewhere around a 3-1/2-inch cut capacity at 90°.

The throat plate is the oblong, removable piece surrounding the blade that sits flush with the table. Taking this piece out allows blade changes. It’s important to have a zero clearance throat plate – one just wide enough the allow the blade’s kerf to pass through – for two reasons. First, zero clearance means no small pieces of material can get lodged or fall between the throat edge and the blade. Second, it provides material support very close to the cut which minimizes tearout as the blade exits the cut.

Framing work is full of rough cuts that rarely makes use of more than one blade at a time. But cabinetry and other woodworking activities often require dados for joinery. If that’s the case, be sure to find out the saw’s dado stack capacity. It’ll require a longer arbor and you won’t be able to use a zero clearance throat plate for it!

Dust Collection

There’s no doubt about it: dust created during a table saw cut is hazardous to your health. Respirable particles fly everywhere where you can easily breathe them in. They wreak havoc on your lungs. That dust also messes up your shop and can get into motors and gears causing more problems down the line. That’s why dust collection is so important – especially when working indoors. Even outside, try to avoid breathing in the dust.

When working in enclosed spaces with a Benchtop, Jobsite, or Contractor table saw, take advantage of the saw’s dust collection port by attaching a collector’s hose and turning it on. We often see Cabinet table saws with a combination blade guard and dust collection system suspended above the blade. We’ll talk more about the blade guard in just a moment, but some saws also have a dust chute on them.

General Safety

We need to respect all tools and remember that whatever they can do to hard material like wood and stone they can do to our bodies. But the rapidly spinning, exposed blade of the table saw warrants an extra measure of caution. Sure, other saws have spinning blades, but it’s the raw power and the potential for injurious kickback and flying shrapnel that makes the table saw particularly dangerous. To avoid these situations, never start the saw with wood touching the blade and never cut so that the waste material is between the blade and fence.

Be sure that the blade brake is quick and in good working order. When you hit the power switch off, you want the blade to stop well within a couple of seconds. This saves you time on the job, ensures you won’t damage the material by moving it before the blade stops spinning, and generally keeps you safe as a still blade is a safer blade.

[adsenseyu2]

We know most of the Pros won’t keep the blade guard on their Benchtops or Jobsites very long, but it’s really best to leave it in place. Many of these blade guards have anti-kickback pawls whose teeth gently bite the wood to keep it from wrenching. This might be unacceptable for finish woodworkers, but at least you have the option.

Riving Knife Vs. Splitter

Be sure the saw has a riving knife and not a splitter. Both components are meant to keep the cut pieces of material separated during the cut. But a riving knife is always the same distance from the blade whereas a splitter is stationary. That means that as you raise and lower the blade, the distance between it and the splitter increases. The further these two get from each other, the more likely it is that a piece of material can cross over behind the blade but in front of the splitter, causing kickback and possibly dangerous shrapnel. Be safe out there!

Final Thoughts

Not all table saws are created equal, and generally speaking, you get what you pay for. But, if you’ve considered your need, you might find that a cheaper, benchtop style table saw is the more practical choice. Or, perhaps you’re planning to launch into a lot of woodworking projects where continual power and runtime is a necessity. In that case, the higher cost and larger spatial footprint of a cabinet saw might be unavoidable.

In any case, the next time you find yourself in Home Depot or Lowe’s and standing in front of aisles’ worth of table saws for sale, we hope that some of the information here helps you choose wisely. If you’re a Pro and you have table saw tips, add them in the comments below—or contact us with your own Pro tips.

Leave a Reply